How Vietnam is Powering the Global Semiconductor Supply Chain

Posted on: July 4, 2025Semiconductors power everything from smartphones and EVs to AI, cloud, and defense systems. As demand accelerates driven by AI and smart tech, supply chains face rising geopolitical and operational risks. This is pushing companies to rethink their semiconductor strategies. Vietnam is emerging as a key player, not just in manufacturing, but in design, packaging, and time-critical semiconductor logistics.

A look at Semiconductor Supply Chain

Step 1. Design & IP (Intellectual Property)

‒ Key countries: United States, Germany, Netherlands, Israel, Japan

‒ Key players: NVIDIA, Qualcomm, ARM, Synopsys, Cadence

This is where the chip begins. Specialized teams design the architecture of processors like CPUs, GPUs, and AI accelerators using Electronic Design Automation (EDA) tools. The final result is a digital blueprint known as the tape-out.

Step 2. Wafer Fabrication (Front-End Manufacturing)

‒ Key countries: Taiwan, South Korea, United States, Japan, China

‒ Key players: TSMC Samsung, Intel

This stage involves transforming pure silicon into wafers etched with millions (or billions) of transistors using extreme ultraviolet lithography (EUV) and other precision processes. Building and running these facilities requires billions in capital and highly controlled cleanroom environments.

Step 3. Assembly, Packaging & Testing (OSAT // Outsourced Semiconductor Assembly & Test) (Back-End Manufacturing)

‒ Key countries: Malaysia, Vietnam, Philippines, China, Mexico

‒ Key players: ASE Group, Amkor Technology, JCET, Intel Vietnam, Unisem

Once wafers are produced, they’re diced into individual chips and packaged to protect them and enable connectivity. Processes like wire bonding, flip-chip, and fan-out wafer-level packaging are common. The chips then undergo electrical and thermal testing before shipment.

Step 04. Final Distribution to OEMs (Original Equipment Manufacturers)

‒ Key countries: China, Vietnam, India, Mexico, Eastern Europe

‒ Key players: Foxconn, Pegatron, Wistron, Luxshare, Compal

In this phase, chips are delivered to the factories that build devices – smartphones, laptops, automotive control units, and more. Integration onto printed circuit boards (PCBs) happens here.

Step 5. Service, Repair & Returns (Post-Sale)

Often overlooked, the post-sale phase includes returns for failure analysis (FA), RMA (Return Merchandise Authorization) procedures, and chip rework. This is essential for quality assurance, warranty service, and customer satisfaction.

Reverse logistics involves traceable, sometimes cross-border returns with strict regulatory compliance – especially for high-value, sensitive components.

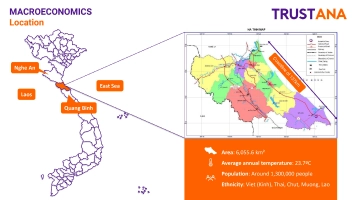

The Role of Vietnam: Moving Upstream

China and Taiwan’s dominance in wafer fabs creates a supply chain bottleneck. Vietnam is stepping in, no longer just a low-cost manufacturing base. It’s building a full-stack presence in the global semiconductor supply chain – design, packaging, testing, and time-critical logistics.

OSAT Is Scaling Fast

‒ Amkor Technology’s factory in Bac Ninh produces System-in-Package (SiP), memory packaging, and electrical testing services – serving global clients in AI, mobility, and high-performance computing.

‒ Intel Vietnam's assembly & test operations (located in Saigon Hi-Tech Park) form Intel’s largest back-end site worldwide, specializing in assembly and testing for mobile, IoT, and data center chipsets.

‒ CT Semiconductor – the first 100% Vietnamese-owned OSAT facility – focuses on cleanroom-based chip packaging, advanced packaging (GaN, photonics, AI/6G integration), and electrical testing, contributing to Vietnam’s national semiconductor ambitions.

IC Design Is Quietly Emerging

‒ FPT Semiconductor launched Vietnam’s first homegrown MCU (Microcontroller) in 2023.

‒ Viettel IC Design, R&D arms at SHTP, and CT Innovation Hub focus on AI, 6G, and photonics – positioning Vietnam to reduce dependency on foreign design hubs.

Time-Critical Logistics: The Backbone of Semiconductor Success

Design gets the headlines. Fabs get the funding. But logistics keeps the ecosystem moving – often invisibly, always urgently.

Semiconductors Don't Wait

Every stage of the chip supply chain is time sensitive. A 24-hour delay in shipping a lithography mask, die, or tool can halt a production line worth million. OEMs operating on just-in-time systems cannot afford a missed connection.

That’s why Next Flight Out (NFO), Onboard Courier (OBC), and expedited customs clearance are not luxuries – they’re essential.

Precision Isn’t Just for Chips

Semiconductor components require extremely tight transport conditions:

‒ Temperature-sensitive items (e.g., wafers, photoresist) need 2–8°C control or cryogenic packaging.

‒ ESD protection is critical – one static discharge can ruin a high-value IC.

‒ Shock, humidity, and vibration must all be minimized in transit.

Best-in-class logistics practices

‒ Cleanroom-compliant packaging

‒ Real-time monitoring (shock/temp)

‒ Dedicated aircraft handling and secure customs routing

Cross-Border = High Risk

With chipmaking spanning multiple continents – design in the U.S., wafers in Taiwan, packaging in Vietnam – cross-border logistics is the supply chain's bloodstream.

Time-critical logistics providers help mitigate risk by:

‒ Pre-clearing documentation

‒ Using bonded warehouses and FTZs

‒ Offering DAP/DDP/DDU delivery models tailored to urgency

In today’s semiconductor race, speed, resilience, and supply chain agility are as critical as nanometer scale. Logistics is no longer a backend function – it’s a core strategy.

❝The difference between “just on time” and “too late” is measured in seconds – not days.❞

Looking for a semiconductor logistics partner in Vietnam that understands urgency, precision, and global connectivity?

Trustana Vietnam specializes in Time-Critical Logistics for semiconductors, electronics, and high-value components. Let’s talk!

+84 966 814 138

+84 966 814 138 ceo@trustana.vn

ceo@trustana.vn